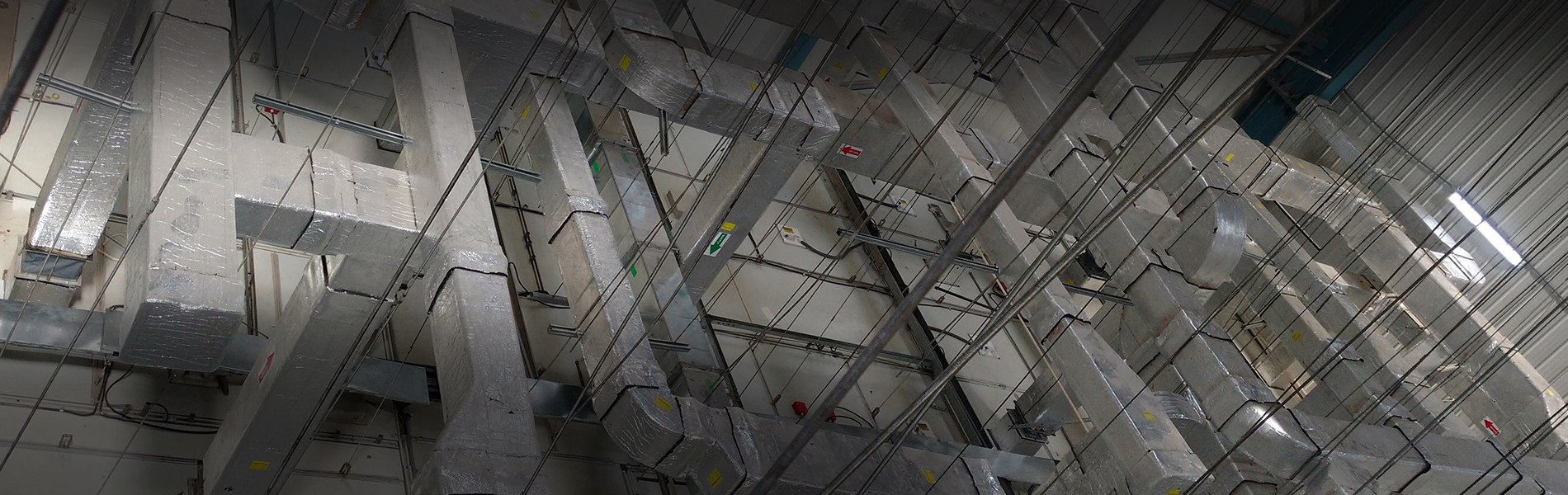

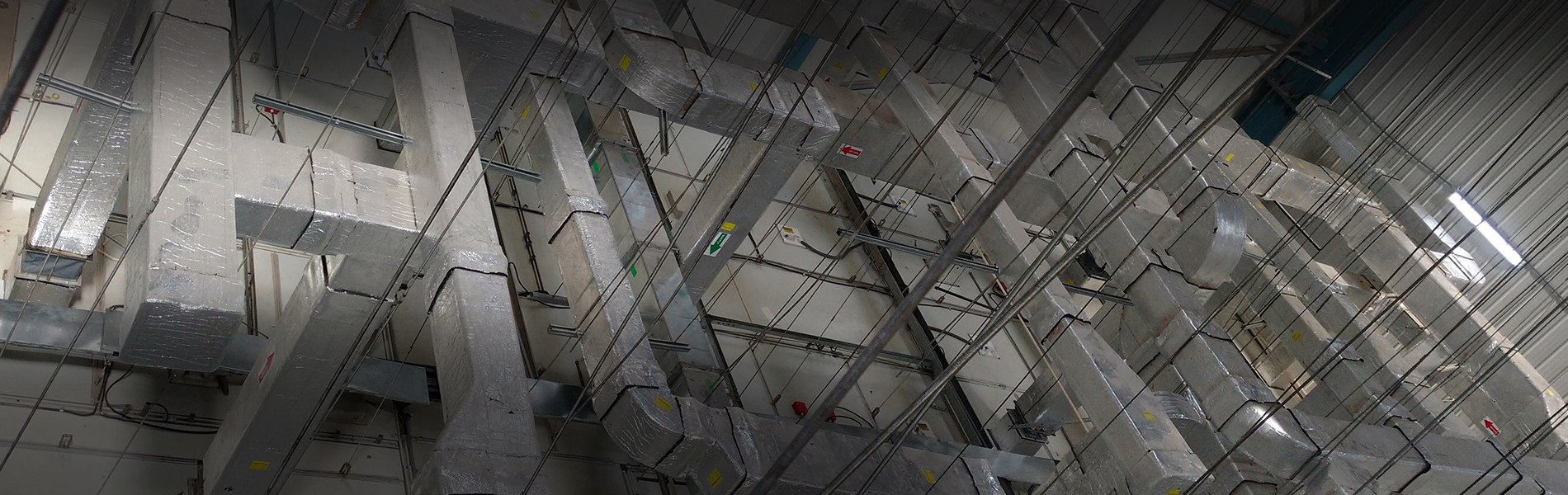

Ducting

Ducting plays a crucial role in Air distribution contributing to the functioning of the entire HVAC system

Are your duct profiles and sections best in quality? Why compromise on ducts while using best in class AHUs? iClean uses leading edge technology for sheet metal fabrication and profiling technology. State-of-the-art- CAD/CAM machines ensures perfectly dimensioned parts and well-fitted sections

Efficient manufacturing dramatically reduces fabrication and therefore job completion time.

Air flow problems have plagued the HVAC industry for years. No matter how much money you spend on a high-quality HVAC system, the equipment won’t work at its best without properly designed and installed ductwork. Ducts that are not well designed result in discomfort, high energy costs, bad air quality, and increased noise levels. A well-designed ductwork system should deliver maximum interior comfort at the lowest operating cost while also preserving indoor air quality.

GI Sheets Galvanized Steel : It is a standard, most common material used in fabricating ductwork for most comfort air conditioning systems. The specifications for galvanized steel sheet are ASTM A653, coating G90. All ducts are fabricated either from Galvanised Sheet Steel (GSS) conforming to IS: 277

Aluminium : It is widely used in clean room applications. These are also preferred systems for moisture laden air, special exhaust systems and ornamental duct systems. The specifications for Aluminium sheet are ASTM B209, alloy 1100, 3003 or 5052.

Stainless Steel : It is used in duct systems for kitchen exhaust, moisture laden air, and fume exhaust. The specifications for stainless steel sheet are ASTM A167, Class 302 or 304, Condition A (annealed) Finish No.4 for exposed ducts and Finish No. 2B for concealed duct.

Flexible ducts : Flexible Duct is a round, flexible light weight duct and is preliminary used for –

Round Ducts :